- press_brake_tools

Raw Materials for Press Brake Tools – Bending Punch and Die

Raw Materials for Press Brake Tools – Bending Punch and Die

The Material mostly is used for press brake tools are variable based in the application and design of the press brake tools. These days the common material being used for the bending tools for press brake machine is German standard 1.7225 or called 42CrMo4 Alloy steel.

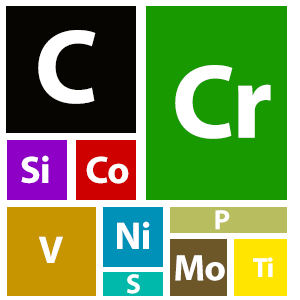

This material has following average percentage of elements in its composition: Carbon: 0.41 % – Silicon 0.30% – Manganese 0.70% – Chromium 1.10% – Molybdenum 0.20%

Heat treatment for 42CrMo4 Press Brake Tools - Bending tools

In order to make the heat treatment and achieve the proper hardness from 42CrMo4 Material need to be heated up to 830 – 860 ˚C to be quenched with oil or it can be heated up to 820 – 850 ˚C to be quenched with water.

The annealing temperature for 42CrMo4 is happening in 680 – 720 ˚C.

What are usual materials for Press Brake Tools (mold)?

- Cr12MoV

- 42CrMo

- T10 Steel

- Cr5MoV

Slide 1 Heading

Lorem ipsum dolor sit amet consectetur adipiscing elit dolor

Click Here

Slide 2 Heading

Lorem ipsum dolor sit amet consectetur adipiscing elit dolor

Click Here

Slide 3 Heading

Lorem ipsum dolor sit amet consectetur adipiscing elit dolor

Click Here

Previous

Next